One of the many significant benefits of Professional Steel is its suitability for induction use, if the pan is produced with a thick gauge. Aluminum, copper and stainless steel all have different advantages for use in cooking utensils. For example, aluminum and copper both heat up very evenly, without any hot spots; while stainless steel is very durable with a non-reactive, corrosion-resistant surface. However, these metals all have a common feature which is disadvantageous for the modern cook: they are all non-magnetic. In fact, 15 or 20 years ago this non-magnetism feature would not have been considered a disadvantage because back then induction cooking tops were not widely available in the market. But in recent years sales of induction cooking tops have grown markedly. The benefits of this type of cooking top surface include: safer to use (they are not hot to touch), and an extremely efficient heat conduction.

In order to make aluminum, copper and stainless steel pans suitable for induction use many are fitted with a special, steel plated bottom. However, not only does this plate add a significant extra cost to the pan’s unit price, but there are also aesthetic reasons why it is often not impact-bonded to the bottom to the pan. For example, an induction-plated bottom would detract from one of copper cookware’s main selling points: its elegant, highly attractive appearance (especially when hung up in a Julia Child-style kitchen). Likewise, many cookware distributors do not want to impact-bond an induction-plated bottom to aluminium because they would prefer a silk-printed design cover at the back of the pan. Aluminum’s light weight is especially suitable for young children to use, and an attractive, eye-catching silk-printed design at the back is an extra benefit for a pan targeting this type of consumer.

In order to make aluminum, copper and stainless steel pans suitable for induction use many are fitted with a special, steel plated bottom. However, not only does this plate add a significant extra cost to the pan’s unit price, but there are also aesthetic reasons why it is often not impact-bonded to the bottom to the pan. For example, an induction-plated bottom would detract from one of copper cookware’s main selling points: its elegant, highly attractive appearance (especially when hung up in a Julia Child-style kitchen). Likewise, many cookware distributors do not want to impact-bond an induction-plated bottom to aluminium because they would prefer a silk-printed design cover at the back of the pan. Aluminum’s light weight is especially suitable for young children to use, and an attractive, eye-catching silk-printed design at the back is an extra benefit for a pan targeting this type of consumer.

With stainless steel cookware the question of whether to add an induction plated bottom is a bit more complicated. There are in fact 3 main types of stainless steel and the one that isn’t induction safe is the stainless steel that is generally used for cookware utensils; this is austenite steel. The reason why most cookware suppliers use austenite stainless steel for cookware is that it contains a much higher amount of nickel compared to the other two types of steel, ferritic and martensitic.. Nickel has two main benefits for stainless steel cookware, the first is that along with chromium it provides a stronger barrier between the iron and oxygen to prevent corrosion, and the second is that a high nickel content makes stainless steel shinier and so more attractive for daily cooking use.

With stainless steel cookware the question of whether to add an induction plated bottom is a bit more complicated. There are in fact 3 main types of stainless steel and the one that isn’t induction safe is the stainless steel that is generally used for cookware utensils; this is austenite steel. The reason why most cookware suppliers use austenite stainless steel for cookware is that it contains a much higher amount of nickel compared to the other two types of steel, ferritic and martensitic.. Nickel has two main benefits for stainless steel cookware, the first is that along with chromium it provides a stronger barrier between the iron and oxygen to prevent corrosion, and the second is that a high nickel content makes stainless steel shinier and so more attractive for daily cooking use.

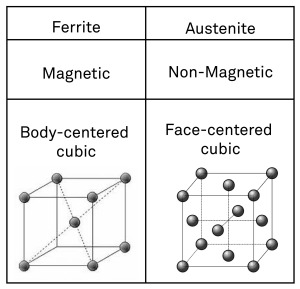

However, this high nickel content has a disadvantage – it means the unit cells within the space formation of austenite steel, and also of aluminum and copper, are all arranged in a face-centered cubic. This unit cell is cubic in shape, with atoms at the eight corners and one atom located in the middle of each of the six faces. A metal with this type of unit cell is not magnetic and therefore cannot be used on an induction cooking top.

As was explained in this blog post, Professional Steel cookware is not alloyed with large amounts of other elements, such as chromium or nickel. Apart from the element carbon, which gives the steel its strength, Professional Steel is almost made up of pure iron. It is the high concentration of this element, along with the absence of nickel, that makes Professional Steel pans Induction Safe. This is because during the production process this type of steel composition forms as ferritic steel, not austenitic. Ferritic steel is highly magnetic, having a unit cell called body-centered cubic, which is also cubic in shape but has only 9 atoms instead of 14..

As was explained in this blog post, Professional Steel cookware is not alloyed with large amounts of other elements, such as chromium or nickel. Apart from the element carbon, which gives the steel its strength, Professional Steel is almost made up of pure iron. It is the high concentration of this element, along with the absence of nickel, that makes Professional Steel pans Induction Safe. This is because during the production process this type of steel composition forms as ferritic steel, not austenitic. Ferritic steel is highly magnetic, having a unit cell called body-centered cubic, which is also cubic in shape but has only 9 atoms instead of 14..

So when you use your high quality Professional Steel pan on an induction cooking top surface, you can be sure you won’t need an impact bonded induction bottom for it. This is because the metal in the pan already has a body-centered cubic unit cell which is highly magnetic.