Stir Frying Barbecued Pork Chow Mein

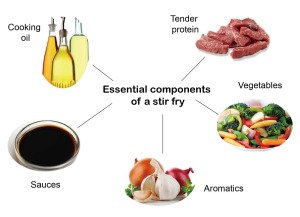

Stir frying is an indispensable cooking technique because any ingredients can be stir fried. A popular stir fry, such as Barbequed Pork Chow Mein, is made up of 5 main components:

- The cooking oil (especially one with a high smoke point)

- Tender protein, such as chicken, beef, pork, seafood, or tofu.

- Vegetables. Add colour, texture, nutritional balance to a dish, and should be as fresh as possible.

- Aromatics. Gives the stir fry distinctive flavours and aromas. Ginger, garlic, lemongrass, herbs, citrus cest, and whole spices such as star anise and chiles can be used and provide flavor highlights to the dish.

- Sauce. Aside from seasoning and adding flavor to the stir fry the sauce helps to finish the cooking of the dish.

All five components can be changed to create a number of different stir fries. In order to use all these ingredients most effectively for a delicious stir fry there are some factors to consider, these include:

- Preparation. For uniform heating ingredients need to be cut into small, even sized pieces. Use of other cooking techniques, such as blanching, can help harder, thicker vegetables retain their flavor and help make the stir frying process even faster. Cutting off the fat and a quick marinate are a good way to prepare meat before starting stir frying. Lastly, proteins and vegetables must be as dry as possible prior to stir frying to ensure that they are sear and not steam in their own juices.

- Timing. The goal of stir frying is to time the cooking so that each ingredient is added best when the stir fry is done, which is why ingredients are cooked in stages. Stir fries are at their most delicious as soon as they are made, so be sure to serve them immediately.

- Handling high heat effectively. Not only should the wok be pre-heated over a high heat but it is vital that high heat is maintained throughout the entire cooking process. For stir frying there should always be a constant and lively sizzle.

Out of the three factors listed above for good stir frying, only the preparation and timing depend solely on the chef’s particular ability, while handling high heat effectively is in part dependent upon the right type of stir wok being used. For an excellent stir fry a consistent, high heat is especially important; with a high heat ingredients will sizzle and fry to impart a special caramelized and smoky flavor on each ingredient. However, if the wok is not hot enough the ingredients will not be seared, but instead be steamed or boiled. Meat, for example, if not stir fried at a high enough temperature will become grey and rubbery.

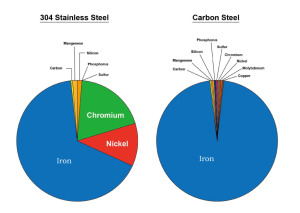

One type of material that is commonly used for a stir wok is stainless steel. This material has a few advantages for a cooking technique such as stir frying. First, it has excellent scratch resistance, a metal spatula can be used to quickly flip and move ingredients quickly around the wok without damaging or visibly impairing the surface. Second, as was shown in the previous blog post, stainless steel is, just like with carbon steel, a highly dense material. With this comes a high heat capacity, so when food is added to the wok heat will not easily escape and the temperature will not significantly drop. Third, stainless steel has a non-reactive surface. With the addition of chromium and nickel to its material composition, stainless steel has both excellent corrosion and colour staining resistance.

However, it is that last benefit for stainless steel, its high alloy content with chromium, nickel and other elements, which gives it some considerable disadvantages for a cooking utensil, especially so for a stir wok. The main disadvantage of alloying a high amount of chromium and nickel with steel is that it prevents a natural non-stick patina from forming on the surface of the stir wok, which is obtained through continual seasoning and intense usage. In contrast the pores of a carbon steel wok can, just like with cast iron, be seasoned to develop a natural, black non-stick surface. Although the disadvantage of a reactive surface for some cooking, such as with deglazing, is that the steel is prone to colour staining if an acid is used during cooking, the majority of ingredients for stir frying are made of up proteins and starches, with very little acid involved. For most stir frying recipes acidic ingredients are mostly only found in the sauces, which are only used lightly at the end of the cooking process. Once a pan is properly seasoned, even a small amount of soy sauce used to finish the stir fry dish would not be enough to significantly react with the carbon steel surface. Moreover, because stainless steel woks cannot develop a natural non-stick patina, they require more oil than a patina non-stick, carbon steel wok to prevent food from sticking. Conversely, if too much oil is used in a stir fry then the food can become quite greasy, which would detract from the fresh, rich flavours of the other components in a stir fry, such as the vegetables, aromatics or sauces mentioned above.

In addition to its lack of non-stick release, another disadvantage of stainless steel’s high alloy content is its poor electrical conductivity. For a stir fry to be a success it needs to happen very quickly, while at the same time being fried at a very high heat. This is particularly important for stir frying vegetables as it helps to maintain the colour, flavor and nutrients of them. A stainless steel stir wok on the other hand would not be able to maintain as much of the flavor of meats and vegetables than a carbon steel wok as it takes a longer time to heat up, and it also has hot spots for uneven heating. The slow and uneven heating effect of stainless steel is not a good combination for a cooking utensil such as a stir wok, because as was explained above, handling high heat effectively is essential for a successful stir fry.

In addition to its lack of non-stick release, another disadvantage of stainless steel’s high alloy content is its poor electrical conductivity. For a stir fry to be a success it needs to happen very quickly, while at the same time being fried at a very high heat. This is particularly important for stir frying vegetables as it helps to maintain the colour, flavor and nutrients of them. A stainless steel stir wok on the other hand would not be able to maintain as much of the flavor of meats and vegetables than a carbon steel wok as it takes a longer time to heat up, and it also has hot spots for uneven heating. The slow and uneven heating effect of stainless steel is not a good combination for a cooking utensil such as a stir wok, because as was explained above, handling high heat effectively is essential for a successful stir fry.

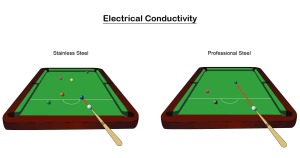

So why does stainless steel’s high alloy content make it have a poorer electrical conductivity than carbon steel? Electrical conductivity in metals is a result of the movement of electrically charged particles. Metals have extra valence (outer shell) electrons which wander throughout the metal structure, not belonging to any one atom. The biggest factor giving different conductivities for metals is the difference in how far these electrons can go before they hit something. Therefore, the transfer of energy is strongest when there is little resistance. As Martin Bell, a Metals Expert, explains:

“Free electrons move through the metal much like billiard balls knocking against each other, passing an electric current as they move…..when a ball strikes against another ball, passing most of its energy on to the next ball. If a single ball strikes multiple other balls, each of those will carry only a fraction of the energy”.

“Free electrons move through the metal much like billiard balls knocking against each other, passing an electric current as they move…..when a ball strikes against another ball, passing most of its energy on to the next ball. If a single ball strikes multiple other balls, each of those will carry only a fraction of the energy”.

Therefore, a metal such as stainless steel, which is an alloy of several elements, has electrons which bounce off all the irregularities in the arrangement of the different atoms. As shown with the billiard table analogy, the extra alloying elements (the snooker balls) on the table slow down the passing of the electric current (the white ball). While the valence electrons of carbon steel do not move as freely as those in copper or aluminum, there are fewer irregularities in the carbon steel metal structure than compared to stainless steel, and so the electric current (the high heat conducted through the stir wok) can be transferred a lot faster.

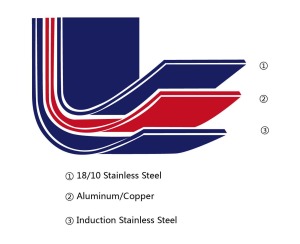

Some manufacturers of stainless steel stir woks improve the electrical conductivity of a stir wok through a production technique called cladding. For this, a highly conductive metal, such as copper or aluminum, is bonded between two layers of stainless steel. However, although this type of production technique (this is commonly referred to as tri-ply stainless steel) might be beneficial for a cookware utensil such as a frying pan, which performs better when it has a uniform heat conduction, for a stir wok it is not as advantageous. First of all, although cladding does remove hot spots from a stainless steel wok, it still does not make the wok heat up faster than a carbon steel wok. This is partly because it actually disperses the heat too well, much of the heat gets conducted to the sides of the wok, when in fact for a good stir fry you want as much of the heat as possible to be concentrated at the centre. In addition, conducting a high amount of heat to the sides of the wok can actually diminish the colour and flavour of some of the stir fried food. This is because quite often after food has been fried to the correct texture and colour, it is then moved up the wok to cool down and if too much heat is conducted to that part of the wok then the food might over-cook and dry out.

Some manufacturers of stainless steel stir woks improve the electrical conductivity of a stir wok through a production technique called cladding. For this, a highly conductive metal, such as copper or aluminum, is bonded between two layers of stainless steel. However, although this type of production technique (this is commonly referred to as tri-ply stainless steel) might be beneficial for a cookware utensil such as a frying pan, which performs better when it has a uniform heat conduction, for a stir wok it is not as advantageous. First of all, although cladding does remove hot spots from a stainless steel wok, it still does not make the wok heat up faster than a carbon steel wok. This is partly because it actually disperses the heat too well, much of the heat gets conducted to the sides of the wok, when in fact for a good stir fry you want as much of the heat as possible to be concentrated at the centre. In addition, conducting a high amount of heat to the sides of the wok can actually diminish the colour and flavour of some of the stir fried food. This is because quite often after food has been fried to the correct texture and colour, it is then moved up the wok to cool down and if too much heat is conducted to that part of the wok then the food might over-cook and dry out.

In addition, the extra weight of cladding another metal between two layers of stainless steel makes the wok quite heavy for stir frying. This is an extra burden for the consumer when you consider how much tossing and flipping is needed for a stir wok (especially as this type of cooking utensil can often have a diameter as wide as 35cm). Lastly, cladding stainless steel with an expensive metal, such as aluminum or copper, increases the price of the wok quite considerably. When you consider the limited number of benefits included with a tri-ply construction for a stainless steel stir wok, the extra cost is not a worthwhile investment.

Conclusion

With stir frying you can take any ingredient, whether it is a tender protein, or from a variety of different vegetables, and transform it into a delicious meal. To use these ingredients for a successful stir fry, for instance a popular dish such as Barbecued Pork Chow Mein, it is all about good preparation, excellent timing and handling high heat effectively. In order to get a high heat to reach the ingredients quickly and at a high concentration, the correct type of material needs to be used for the stir wok. Although a commonly used material such as stainless steel does have a number of advantages for cooking, such as high scratch and corrosion resistance, it is not a very suitable metal for stir frying. Not only does its high alloy content mean that a lot of cooking oil has to be used for a good non-stick effect, which can make the stir fry unnecessarily greasy, but the inclusion of elements such as chromium and nickel into the metal structure actually slow down the electrical conductivity of stainless steel. A Professional Steel wok has a much lower alloy content than stainless steel, and so does not have as many irregularities within the lattice that forms its physical structure. This in turn means that the free valence electrons of carbon steel can move more freely, and so conduct electricity more quickly and evenly for an all-round better heating effect for stir frying than stainless steel. Although the electrical conductivity of a stainless steel wok can be improved through the inclusion of a tri-ply construction, this will still not concentrate and transmit heat to the stir fried ingredients as quickly as a carbon steel wok. Also, aside from being quite heavy, stainless steel tri-ply woks can be quite expensive with very little added benefit.