When a consumer purchases an item from a retail store or online, they want to know not only is it safe to use but also that it has been sourced responsibly. A product at the end of the manufacturing process might look in good quality, but this attractive appearance might obscure its poor quality within. If the various materials to make the product were not sourced from reputable suppliers then the product may not pass a general health safety test, or it may not perform to as high a standard as expected.

Steel Sourcing

Some producers of carbon steel for cookware don’t make the steel in a processing plant but instead use recycled steel scrap from old, disused barrels, most of which still have some toxic chemical residue on the steel surface. The first stage of this carbon steel cookware production process involves cutting the barrel into a wide shape, flattening it through the rolling process, and then stamping the steel into a round, metal disk. In contrast to this basic type of manufacturing process, the material for all Professional Steel pans is purchased directly from the steel processing plant. As explained in more detail here, the steel arrives at the Professional Steel factory in a coil (as shown above), already cut at the exact, specified dimensions, for it to be later stamped into a steel disk.

Scrap Steel Storage Barrels

Rolling Process

Stamping

Steel Disk

Steel Pre-treatment

After the steel is stamped into a round disk shape at the BSCI/ Sedex/ ISO 9001 certified Professional Steel factory, it can be spun immediately into the desired cookware shape. This could be, for example, a frying pan, stir wok or paella pan. From there the steel pan is given a pre-wash, with no chemical treatment involved, to remove the oil on the pan. Later the pan is then dried to prepare it, first for grit blasting (the benefits of which are explained here) and then later for the application of the glaze wax coating (the benefits of which are explained here and here).

After the steel is stamped into a round disk shape at the BSCI/ Sedex/ ISO 9001 certified Professional Steel factory, it can be spun immediately into the desired cookware shape. This could be, for example, a frying pan, stir wok or paella pan. From there the steel pan is given a pre-wash, with no chemical treatment involved, to remove the oil on the pan. Later the pan is then dried to prepare it, first for grit blasting (the benefits of which are explained here) and then later for the application of the glaze wax coating (the benefits of which are explained here and here).

However, for some carbon steel cookware on the market today, factories do not use the same Professional Steel chemical-free, safety-first approach pre-wash process. This is because, as mentioned above, the material that arrives at the factory is not fresh from a steel processing plant. Instead it is often sent from another factory which has made round steel disks from disused steel barrels. Therefore, before these steel pans can be sprayed with a corrosion resistant coating, harmful chemicals and other residue on the steel, such as sulfuric or hydrochloric acid, must be removed. But whereas a simple wash and dry is sufficient to remove the oil from a Professional Steel pan, for the steel cookware made from recycled barrels, it needs a more thorough wash. This type of pre-wash would be with highly potent chemicals, which although would properly remove the clearly visible residue on the steel surface, some of these chemicals would still remain on the surface of steel.

However, for some carbon steel cookware on the market today, factories do not use the same Professional Steel chemical-free, safety-first approach pre-wash process. This is because, as mentioned above, the material that arrives at the factory is not fresh from a steel processing plant. Instead it is often sent from another factory which has made round steel disks from disused steel barrels. Therefore, before these steel pans can be sprayed with a corrosion resistant coating, harmful chemicals and other residue on the steel, such as sulfuric or hydrochloric acid, must be removed. But whereas a simple wash and dry is sufficient to remove the oil from a Professional Steel pan, for the steel cookware made from recycled barrels, it needs a more thorough wash. This type of pre-wash would be with highly potent chemicals, which although would properly remove the clearly visible residue on the steel surface, some of these chemicals would still remain on the surface of steel.

Testing Requirements for Steel Cookware

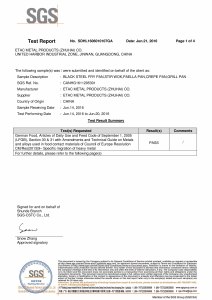

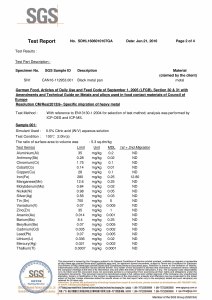

To demonstrate that the material for Professional Steel is sourced from reputable suppliers and that the pans are produced in a factory which treats the steel without any harmful chemicals, Professional Steel has sent its pans to well-known and respected independent testing companies such as SGS and TUV. Not only have Professional Steel pans been tested in accordance with LFGB (German), EEC (European) and FDA (USA) food safety regulations, but the factory in which the pans are made has been audited according to BSCI and Sedex regulatory requirements.

As you can see below, a Professional Black Steel frying pan and paella pan have both just recently passed a strict LFGB extractable heavy metal test.

Conclusion

Carbon steel cookware that is sourced from producers that use recycled barrels, and which are made in factories that do not adhere to strict safety and quality control regulations for its pre-wash process, will not pass LFGB and FDA testing regulations. Perhaps some wholesalers for cookware would prefer to make and sell a cheaper product to increase their profit margin or market share. However, if a consumer purchases a Professional Steel pan, they can know for sure that they are using a pan which can cook food safe for human consumption. Not only is this steel material sourced directly from the steel processing plant, but it is not treated with certain chemicals that would make the product fail an LFGB extractable heavy metal test.