As noted here, for steel cookware a protective lacquer coating has many disadvantages compared to a Professional Steel glaze wax coating. Some of these disadvantages include: difficulty to remove; potential damage to the cooking top surface; and a number of safety hazards. A glaze wax coating on the other hand has none of these problems, which is one of the reasons why Professional Steel is sold today in so many countries throughout the world.

However, there is another important quality difference between a lacquer-coated steel pan and a glaze wax-coated pan, and this relates to rust. A web search will reveal a number of consumers in the USA who have written negative reviews about a fairly well-known brand of lacquer-coated stir woks. For the most part these reviews are not about the hassle or danger of removing the lacquer coating, but instead the condition of the pan once they have started using it.

Consumer reviews of a famous brand of lacquer-coated stir woks

“You need to temper it or it will rust to hell after first use.”

“Piece of garbage. I followed all directions regarding seasoning, storage, and usage and the thing is so rusted, it is dangerous to use after only 1/2 dozen uses over the past few months. DO NOT BUY.”

“I went back to my old faithful cast iron wok. My son and I both seasoned our woks before use. Don’t use soap and dry it on the stove. No matter what we do, it keeps rusting. I still have it but I don’t use it any longer because I’m afraid it is a health hazard.”

“Very hard to season. I had seasoned it four times. But every time after cooking, it still rusts. I have never had a wok as bad as this one. Would not recommend.”

“Very first day after washing I saw a huge rust. All the cooked items with this product looks a bit black in color relative to other. I don’t like this product and planning to return.”

“After one use, the pan began to rust — there is a thin layer of rust that appears and is impossible to scrub off. Not worth the money.”

Why does a lacquer-coated stir wok have a rust problem?

To remove a lacquer coating the consumer has to heat the pan to a very high temperature, which affects the steel’s suitability for cooking. After the lacquer coating has been removed the steel is very hot, so when water is added the steel reacts to it very quickly, causing rust to appear much more quickly than it would if the pan were just heated normally for cooking.

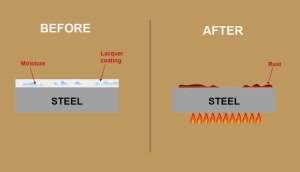

Another factor to consider is the problem of rust while the product is transported. A lacquer coating prevents the pan rusting during transportation from the factory to the retail store, but also retains any moisture which was on the pan’s surface before it was coated. Pans are pre-washed before coating and it is very difficult to remove all moisture from their surface before the lacquer is sprayed on. This residual moisture is trapped underneath the coating, so rust can develop very quickly when a consumer removes the coating – which might explain many of the complaints about the poor corrosion-resistance of the famous brand of lacquer-coated stir woks mentioned previously.

Why do Professional Steel glaze wax-coated steel pans have fewer problems with rust for first-time use?

A Professional Steel glaze wax coating prevents moisture developing on the pan’s steel surface and causing rust, just as a lacquer coating does. However, unlike a lacquer coating, a glaze wax coating does not trap moisture between it and the pan. This is because a glaze wax coating is much thinner than a lacquer coating and allows some of the moisture to escape. Further, a Professional Steel glaze wax coating can be removed by heating the pan to a much lower temperature than is needed to remove a lacquer coating. Consequently, a glaze wax-coated steel pan is available for first use in a well-conditioned state and will not rust as easily as a lacquer coated pan.